Condensate Return & Boiler Feed Pumping Units

- Available in both Simplex and Duplex styles

- Achieve substantial energy savings

- Lower operating costs by reusing condensate

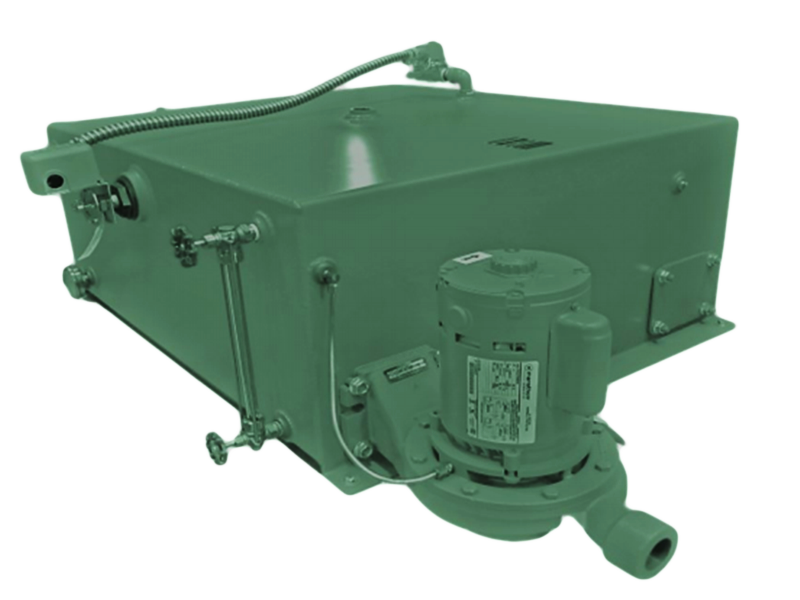

Condensate Return Pumping Units are packaged assemblies consisting of a receiver (either Cast Iron or Steel), Pump and Motor (either Simplex or Duplex) and control device to turn the pump motor on or off.

Keystone is a supplier of Evergreen®, Shipco, Mepco, Hoffman, Price and other models.

Available Evergreen® Units

Select the category of Evergreen® products you are interested in getting more information on and then scroll the chart for an overview of what’s available.

Please contact us for questions, quotations and inquiries. Or for information on Shipco, Mepco, Hoffman, Price and other models.

Contact Us

Do you still have questions? Are you looking for pricing information or to place an order?

Do you have questions about condensate pumping units?

Does Keystone only sell Evergreen® units?

No, we can sell condensate return pumping units from any manufacturer, including Shipco, Mepco, Hoffman and other brands.

What are condensate return pumping units?

Condensate Return Pumping Units are packaged assemblies consisting of a receiver (either Cast Iron or Steel), Pump and Motor (either Simplex or Duplex) and control device to turn the pump motor on or off. They are designed to collect condensed liquid at remote locations in a steam system and move it back to the boiler room. The Units can be powered by either electricity or steam. Electrically powered units are the norm while the steam-driven units are typically used in hazardous environments or where electricity may not be readily available.

What options do you need to consider to select the right pumping unit?

- System Capacity (generally a function of boiler horsepower) and determines tank size

- System Type (Vacuum or Gravity)

- Outlet Pressure requirement (which determines motor HP)

- Electrical requirement (single or three phase, voltage)

- Type of motor (TEFC, Explosion-Proof, Open Drip)

- NPSH (determines type of pump)

- Tank material (determines service life of receiver)

- Single or Double Pump Design

- Accessories (e.g. Pressure Gauge, Water Level Gauge Glass, Isolation Valve, etc.)

What are boiler feed pumping units?

Boiler Feed Pumping Units are packaged assemblies consisting of a receiver (either Cast Iron or Steel), Pump and Motor (either Simplex or Duplex) and control device to turn the pump motor on or off (usually controlled by the boiler). They are designed to send condensed liquid from the system, augmenting it with make-up water when required, to the boiler. They are generally larger than the Condensate Return Pumping Unit(s) found in the system as they must store boiler feed water until the boiler calls for additional water. Many of the same criteria as used to select a Condensate Return Pumping Unit are used to select a Boiler Feed Pumping Unit with the additional variables:

- Type of make-up water control (float or solenoid)

- Horizontal or vertical design

What are the benefits of boiler feed pumping units?

- Achieve substantial energy savings by collecting the already heated condensate and returning it to the boiler thereby lowering the consumption of fuel needed to heat the much cooler make-up water.

- Lower operating costs by reusing condensate already chemically treated thereby reducing the consumption of additional chemicals needed to treat fresh make-up water.

What are the features of Evergreen® condensate return pumping units?

• Simplex and Duplex Pump Packages

• Carbon-Steel Tanks or Optional Stainless Steel

• High Efficiency 3450 RPM Motors

• Bronze Impeller, Peak Efficiency Pumps

• Cast Iron Bodies

• Heavy Duty Float Switches and Operating Controls

• Capacities 10,000—50,000 EDR

• Discharge Pressures 20—80 PSIG

• Standard Receiver Sizes: 10-15-30-45-75-95 gallons.

What are the advantages of an Evergreen® pump?

Evergreen® Series Condensate Return Pumps are designed to provide an efficient means of condensate recovery for steam heating systems and steam process applications. A float actuated switch turns the pump on and off based on the water level in the tank.

Evergreen Condensate Pumps are available in simplex and duplex packages.

What are the advantages of an Evergreen® boiler feed recovery system?

Evergreen® Series Boiler Feed Pumps are designed to maintain boiler water level and provide make-up water from an outside

source. A boiler water line control turns the pump on and off when the boiler requires it. Water level in the receiver tank is maintained by using a water make-up valve activated by a reverse acting float switch. If the water in the receiver is inadequate, additional boiler feed water is automatically added to the receiver tank. Some typical applications include gravity return comfort

heating system, low pressure boilers or low pressure process equipment.

What else does Evergreen® offer?

Low Operating Costs

Evergreen® Series designed with high efficiency 3450 RPM motors and peak efficiency pumps which yield lower energy costs. These pumps have long life, high temperature ceramic seals (250°) eliminating the stuffing box designed leakage of valuable condensate. The motors are mounted off the floor in a lower maintenance environment.

Overload Protection

Evergreen® Series Control Panel comes with high quality electrical controls which

provide peak overload protection, featuring across the line magnetic starters and

circuit breakers and are accurately tuned to the specific loading needs of the motors. Units with 2HP and larger motors require an electrical control panel. Smaller

HP motors can be ordered with a control panel providing the same protection

afforded the larger motors.

Oversized Rated Duty

Evergreen® Series units are designed for low NPSH® giving them the ability to

handle high temperature condensate quietly and efficiently at a much higher

then specified EDR. This assures low maintenance and long life. Duplex models

provide 100% stand-by with alternation.